Enhanced TDS

Identification & Functionality

- Chemical Family

- RTU Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Product Features

- Very high shear and peel strength

- Extremely tough and resilient

- Good moisture resistance

- Bonds a wide variety of materials including metal, wood, rubber, glass fiber reinforced composites and many plastics

Applications & Uses

- Application Area

- Compatible Substrates & Surfaces

- Markets

- Applications

- Processing Information

Pretreatment

The strength and durability of a bonded joint are dependant on proper treatment of the surfaces to be bonded. At the very least, joint surfaces should be cleaned with a good degreasing agent such as acetone or other proprietary degreasing agents in order to remove all traces of oil, grease and dirt. Alcohol, gasoline (petrol) or paint thinners should never be used. The strongest and most durable joints are obtained by either mechanically abrading or chemical etching (“pickling”) the degreased surfaces. Abrading should be followed by a second degreasing treatment.

Stir the two components thoroughly together until the two colours are completely blended, without any visible streaks. Automatic mixing / dispensing may be used. Araldite® 420 A/B is also supplied in cartridges incorporating mixers and can be applied as ready to use adhesive with the aid of the tool recommended by Huntsman Advanced Materials.

Usable life

Due to exothermic reaction between the two components the usable life depends to some extent on the usable mixed and the shape of the container. Use of a shallow container will extend the usable life and as a rough guide:

- For a 50gm mix, usable life at 25°C is 2 hours

- For a 100gm mix, usable life at 25°C is 1 hour

Application of adhesive

The resin/hardener mix is applied directly or with a spatula to the pretreated and dry joint surfaces. A layer of adhesive 0.05 to 0.10mm thick will normally impart the greatest lap shear strength to the joint. The joint components should be assembled and clamped as soon as the adhesive has been applied. An even contact pressure throughout the joint area will ensure optimum cure

Curing

Once applied, Araldite® 420 A/B will gel in 2 - 4 hours at 25°C and will be sufficiently cured after 5 hours to allow the bonded component to be handled. After 4 – 5 days the adhesive will obtain 90% of its full strength and achieve full strength after 1 to 2 weeks at room temperature.

- Cure can be accelerated by heating. 4 hours at 50°C or 1 hour at 120°C will be sufficient to achieve full strength.

- Shear properties can be improved, particularly at elevated temperatures, by post-curing for up to 24 hours at 70°C.

Lap shear strength after various cure times at 23°C (typical average values)

5 hours: 1 N/mm² 6 hours: 8 N/mm² 7 hours: 9 N/mm² - Application Information

- Bonding inserts, ferrules, aluminium and composite edge members, joining strips, etc, in both metallic and non-metallic honeycomb sandwich structures.

- Fabrication of composite components using the cut and fold technique.

Properties

- Physical Form

Regulatory & Compliance

- OEM Specifications

Technical Details & Test Data

- Processing Condition

- Pretreatment: The strength and durability of a bonded joint are dependant on proper treatment of the surfaces to be bonded. At the very least, joint surfaces should be cleaned with a good degreasing agent such as acetone or other proprietary degreasing agents in order to remove all traces of oil, grease and dirt. Alcohol, gasoline (petrol) or paint thinners should never be used. The strongest and most durable joints are obtained by either mechanically abrading or chemical etching (“pickling”) the degreased surfaces. Abrading should be followed by a second degreasing treatment.

- Usable life: Due to exothermic reaction between the two components the usable life depends to some extent on the usable mixed and the shape of the container. Use of a shallow container will extend the usable life and as a rough guide: For a 50gm mix, usable life at 25°C is 2 hours For a 100gm mix, usable life at 25°C is 1 hour

- Application of adhesive: The resin/hardener mix is applied directly or with a spatula to the pretreated and dry joint surfaces. A layer of adhesive 0.05 to 0.10mm thick will normally impart the greatest lap shear strength to the joint. The joint components should be assembled and clamped as soon as the adhesive has been applied. An even contact pressure throughout the joint area will ensure optimum cure.

- Curing: Once applied, Araldite® 420 A/B will gel in 2 – 4 hours at 25°C and will be sufficiently cured after 5 hours to allow the bonded component to be handled. After 4 – 5 days the adhesive will obtain 90% of its full strength and achieve full strength after 1 to 2 weeks at room temperature. Cure can be accelerated by heating. 4 hours at 50°C or 1 hour at 120°C will be sufficient to achieve full strength. Shear properties can be improved, particularly at elevated temperatures, by post-curing for up to 24 hours at 70°C.

- Typical Cured Properties

Bell peel 150 N / 25mm (60°C peel using 2024-T3 clad aluminium adherents at 25°C).

Honeycomb bonding results (in accordance with MIL-A-25463)

Beam shear at 22°C: 12kN (core failure)

Flatwise tensile at 22°C: 8.5 N/mm2

Metal: 2024-T3; Core: 7.9 – ¼ - 40 5052

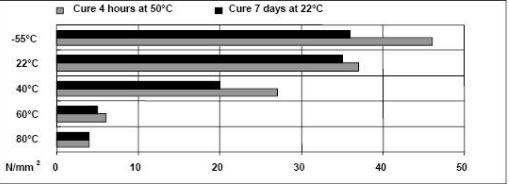

Variation of lap shear strength as a function of temperature (typical average values)

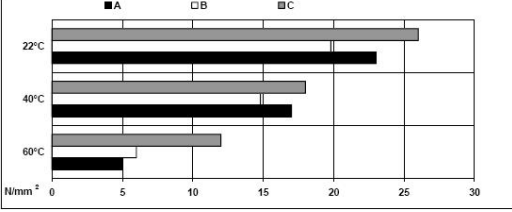

Lap shear strength: variation after exposure to 95% RH at 60°C (typical average values) (cured 7 days at 23°C) C = 30 days exposure A = 90 days + drying for 16 hours at 60° B = 90 days exposure

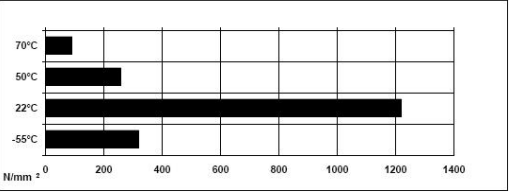

Honeycomb peel performance (typical average values) (cured 7 days at 23°C)

Tested in accordance with MIL-A-25463 using approx. 300g/m2 of Araldite® 420 per skin.

Effect of alternative cure schedules on lap shear strength performance (LSS) (typical average values

Test Results Test methods Cure cycle Test temp (°C) LSS (MPa) 70°C for 1 hour 22 37 A.E.C.M.A. EN2243-1

2 hours 70 4 6 hours 70 6 16 hours 70 11 24 hours 70 10 120°C for 1 hour 70 8 22 43 A.E.C.M.A. EN2243-1

50 29 70 10

Safety & Health

- Handling Precautions

- Our products are generally quite harmless to handle provided that certain precautions normally taken when handling chemicals are observed.

- The uncured materials must not, for instance, be allowed to come into contact with foodstuffs or food utensils, and measures should be taken to prevent the uncured materials from coming in contact with the skin, since people with particularly sensitive skin may be affected.

- The wearing of impervious rubber or plastic gloves will normally be necessary; likewise the use of eye protection.

- The skin should be thoroughly cleansed at the end of each working period by washing with soap and warm water.

- The use of solvents is to be avoided. Disposable paper - not cloth towels - should be used to dry the skin. Adequate ventilation of the working area is recommended.

Packaging & Availability

- Packaging Type

- Regional Availability

Storage & Handling

- Storage Conditions

Araldite® 420 A/B must be stored for up to 30 months at 18 – 40°C and the components must be stored in their original sealed containers

- Storage Conditions

Araldite® 420 A/B must be stored for up to 30 months at 18 – 40°C and the components must be stored in their original sealed containers. The expiry date is indicated on the label.

Other

- Appearance

- Dark green

- Application Information

Value Units Test Method / Conditions Mix Ratio 0.4 %(W) %(W) Hardener : Resin - Physical Properties

Value Units Test Method / Conditions Specific Gravity 1.1-1.2 - Viscosity 35.0-45.0 Pa.s Pa.s