Enhanced TDS

Identification & Functionality

- Chemical Family

- Fillers Included

- RTU Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Product Highlights

- Outstanding mechanical and electrical properties combined with very high crack and thermal shock resistance due to the low coefficient of thermal expansion.

- Qualified for encapsulation of large metal parts.

- Product Features

Wollastonite prefilled system, low thermal exp. Coefficient, high crack resistance, moderate reactivity, UL 746 B recognition for 200°C service temperature.

Applications & Uses

- Application Area

- Compatible Substrates & Surfaces

- Composites Processing Methods

- Cure Method

- Product End Uses

- Markets

- Applications

- Applications

Indoor electrical insulation material for postinsulators, equipment parts, bushings, instrument and dry type distribution transformers, switchgears, etc.

- Processing Information

The effective pot-life of the mix is about 2 to 3 days at temperatures below 25°C. Conventional batch mixers should be cleaned once a week or at the end of work. For longer interruptions of work, the pipes of the mixing and metering installations have to be cooled and cleaned with the resin component to prevent sedimentation and/or undesired viscosity increase. Interruptions over a week-end (approx. 48h) without cleaning are possible if the pipes are cooled at temperatures below 18°C.

Viscosity increase and gel time at various temperatures.

Mould temperature

APG process : 130°C - 160°C

Conventional vacuum casting : 70°C - 100°C

Demoulding times (depending on mould temperature and casting volume)

APG process : 10 min - 40 min

Conventional vacuum casting : 4 h - 8h

Cure conditions (minimal postcure)

APG process 4h at 140°C

Conventional vacuum casting 8h at 130°C

To determine whether crosslinking has been carried to completion and the final proper-ties are optimal, it is necessary to carry out relevant measurements on the actual object or to measure the glass transition temperature. Different gel and postcuring cycles in the manufacturing process could influence the crosslinking and the glass transition tempera-ture respectively.

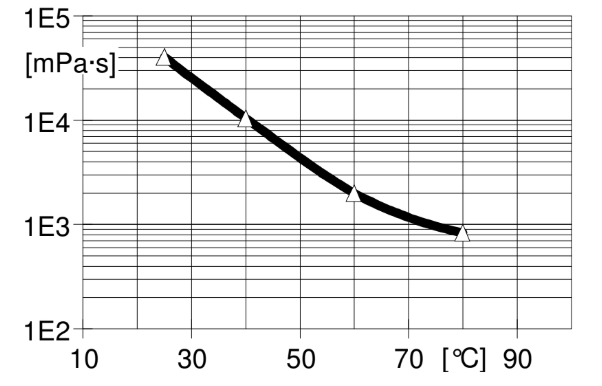

Initial viscosity as a function of temperature

(measurements with Rheomat 115, D = 10 s⁻¹)

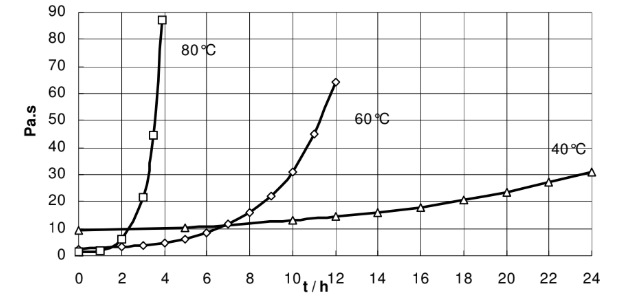

Viscosity increase at 40, 60 and 80°C

(measurements with Rheomat 260, MS 125, shear rate D = 10 s⁻¹)

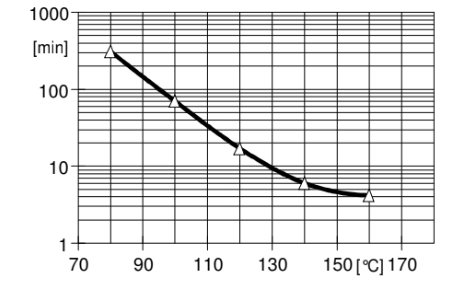

Geltime measured as a function of temperature

(measurements with Gelnorm Instrument / ISO 9396)

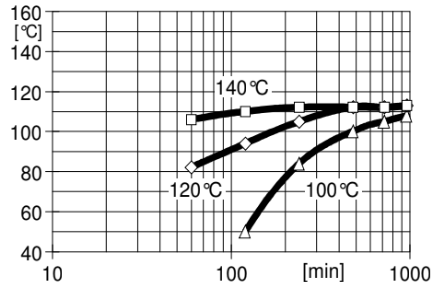

Glass transition temperature as a function of cure time

(isothermic reaction, ISO 11357-2)

- System Preparation

General instructions for preparing prefilled resin systems

Long pot life is desirable in the processing of any casting resin system. Prefilled components help to shorten the mixing time considerably. The two components will be mixed in the desired quantity under vacuum and at slightly elevated temperature (50 - 60°C). For the mixing of medium- to high viscous casting resin systems and for mixing at lower temperatures, we recommend special thin film degassing mixers that may produce additional self-heating of 10-15 °C as a result of friction. Depending on quantity, mixer device, mixing temperature and application, the mixing time is, under a vacuum of 1 to 8 mbar, 0.5 to 2 h. The premixed components packed according to their mixing ratio, could be used per container. In case of filler sedimentation, it is recommended to empty the container completely. Before partial use, the content must be carefully homogenized at elevated temperature. We recommend the same preheating temperature to prevent air enclosures when discharging the components.In automatic mixing and metering installations, both components will be degased and ho-mogenized under a vacuum of about 2 mbar in the holding tanks. When degassed, the prefilled products are stirred up from time to time to avoid any sedimentation. After dosing and mixing with a static mixer, the system is fed directly to the vacuum chamber or, in the automatic pressure gelation process, directly into the hot casting mould. By using circular feeding tubes, several casting stations can be served.

Properties

- Physical Form

Technical Details & Test Data

- Thermal Endurance

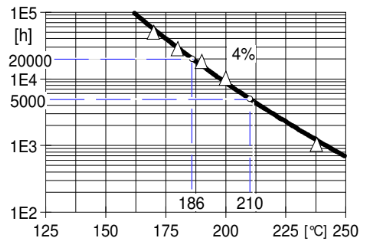

Thermal Endurance

Profile acc. IEC 60216

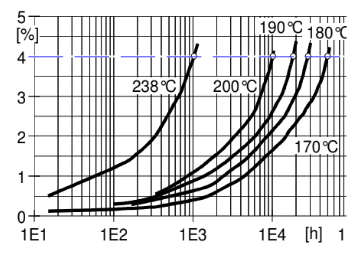

Weight loss

(specimen: 50x50x3 mm, limit: 4.0%)

Temperature Index 186 / 210

(weight loss)

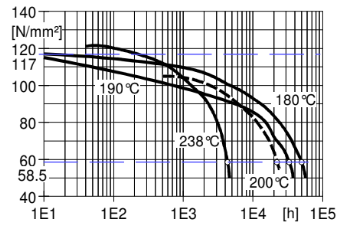

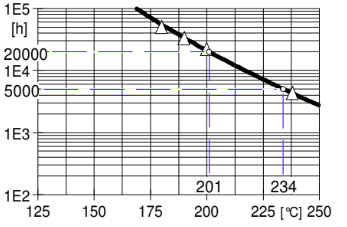

Loss of flexural strength

(ISO 178, limit: 50%)

Temperature Index 201 / 234

(flexural strength)

- Mechanical

Mechanical values

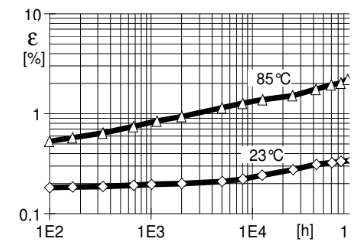

Elongation (ε) as a function of temperature at 23 and 85°C

(Tensile strain: 20 MPa , ISO 899)

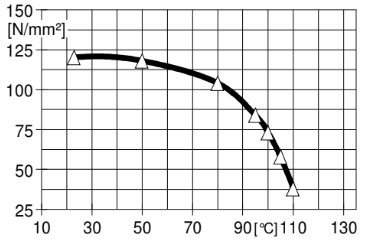

Flexural strength as a function of temperature

(ISO 178)

- Crack Resistance / Combustion Products

Crack Resistance / Combustion Products

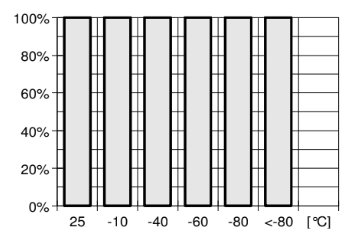

Crack resistance/ Temperature cycling test

Passed specimen (%) = f (temp. steps)

No crack registered till -80°C

Embedded metal part, edge radius 1 mm

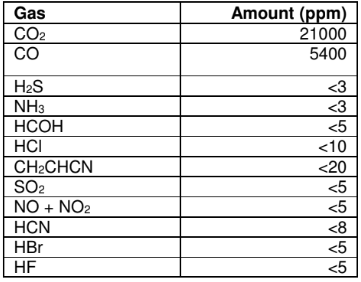

Combustion Products according CEI 60020-37, part 2

Tested by IMQ, Milano, Italy

- Electrical Properties

Electrical Properties

If electrically stressed structural components are to be used under difficult climatic conditions (cf. IEC 60932), the complete installation must be tested climatically under maximum working load.Property Test Method Unit Value Breakdown Strength IEC 60243-1 kV/mm 18 - 22 Diffusion Breakdown Strength DIN VDE 0441-1 class HD 2 Temperature of Specimen After Test - °C < 23 HV Arc Resistance IEC 61621 s 93 – 125 Tracking Resistance IEC 60112 CTI > 600-0.0 Tracking Resistance (Test Solution B) IEC 60112 - -- Electrolytical Corrosion Effect IEC 60426 grade A-1 Loss factor (tan δ) and dielectric constant (εr) as a function of temperature (measurement frequency: 50 Hz / IEC 60250)

Volume resistivity (ρ) as a function of temperature (measurement voltage: 1000 V/ IEC 60093)- Specific Instructions

The effective pot-life of the mix is about 2 to 3 days at temperatures below 25°C. Conventional batch mixers should be cleaned once a week or at the end of work. For longer interruptions of work, the pipes of the mixing and metering installations have to be cooled and cleaned with the resin component to prevent sedimentation and/or undesired viscosity increase. Interruptions over a week-end (approx. 48h) without cleaning are possible if the pipes are cooled at temperatures below 18°C.

Viscosity increase and gel time at various temperatures, refer to Figs: 4.2 and 4.3.

Mould temperature

APG process : 130 - 160°C

Conventional vacuum casting : 70 - 100°C

Demoulding times (depending on mould temperature and casting volume)

APG process : 10 - 40 min

Conventional vacuum casting : 4 - 8h

Cure conditions (minimal postcure)

APG process : 4h at 140°C

Conventional vacuum casting : 8h at 130°CTo determine whether crosslinking has been carried to completion and the final proper-ties are optimal, it is necessary to carry out relevant measurements on the actual object or to measure the glass transition temperature. Different gel and postcuring cycles in the manufacturing process could influence the crosslinking and the glass transition tempera-ture respectively.

- Mechanical & Physical Properties

Mechanical and Physical Properties

Determined on standard test specimen at 23℃

Cured for 10h at 80°C + 10h at 140℃

Property

Test Method

Unit

Value

Tensile strength

ISO 527

MPa

80 - 90

Elongation at break

ISO 527

%

1.3 - 1.5

E modulus from tensile test

ISO 527

MPa

10000 - 11000

Flexural strength

ISO 178

MPa

120 - 130

Flexural strength at 80°C

ISO 178

MPa

100 - 110

Surface strain at 23°C

ISO 178

%

1.4 - 1.6

Surface strain at 80°C

ISO 178

%

2.2 - 2.4

E modulus from flexural test

ISO 178

MPa

9600 - 10000

Compressive strength

ISO 604

MPa

170 - 190

Compression set

ISO 604

%

11 - 14

Impact strength

ISO 179

kJ/m²

9 - 11

Double Torsion Test

CG 216-0/89

-

-

Critical stress intensity factor (KIC)

-

MPa·m¹/₂

2.8 - 3.0

Specific energy at break (GIC)

-

J/m²

670 - 750

Martens temperature

DIN 53458

°C

100 - 110

Heat distortion temperature

ISO 75

°C

105 - 115

Glass transition temperature (DSC)

ISO 11357-2

°C

110 - 125

Coefficient of linear thermal expansion

ISO 11359-2

K⁻¹

27 – 30.10⁻⁶

Thermal conductivity

similar to ISO 8894-1

W/mK

0.65 - 0.75

Flammability (Burning time/-length)

ISO 1210

s/mm

57 / 11

Flammability

UL 94

class

HB

Thermal endurance profile (TEP)

IEC 60216

-

-

Temperature index (TI): weight loss

-

°C

TI 186 / 210

Temperature index (TI): flexural strength

-

°C

TI 201 / 234

Thermal ageing class

IEC 60085

class

H

Thermal endurance RTI: tensile strength

UL 746B

°C

200

Thermal endurance RTI: dielectric strength

UL 746B

°C

200

Water absorption (specimen: 50x50x4 mm)

ISO 62

% by wt.

0.10 - 0.20 (10 days at 23°C)

Water absorption (specimen: 50x50x4 mm)

ISO 62

% by wt.

0.10 - 0.20 (60 min at 100°C)

Decomposition temperature

TGA

°C

400

Density (Filler load: 61% by wt.)

ISO 1183

g/cm³

1.80 - 1.90

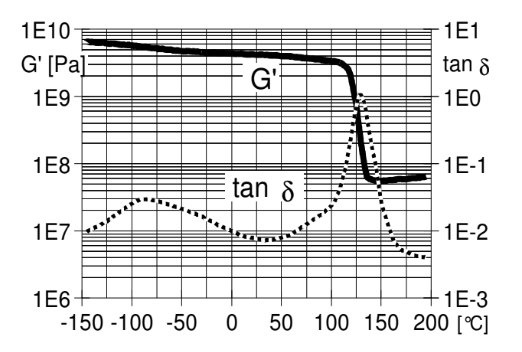

Shear modulus (G') and mechanical loss factor (tan δ) as a function of temperature

(ISO 6721-7,methode C, measured at 1Hz)

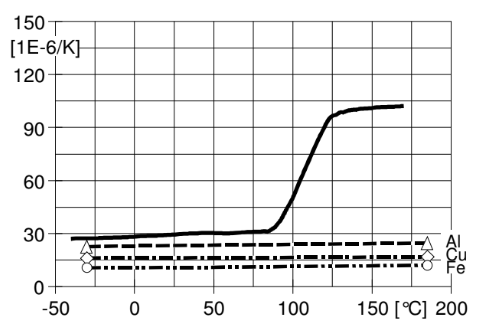

Coefficient of linear thermal expansion (α) as a function of temperature

(ISO 11359-2/ reference temperature: 23°C)

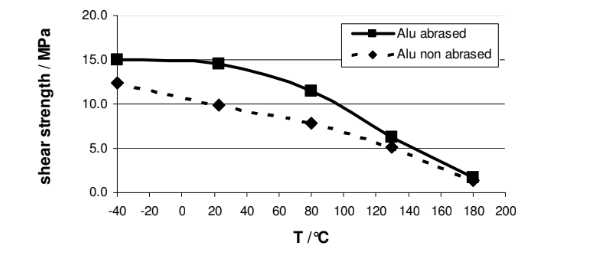

Tensile lap-shear strength (MPa) vs. temperature and surface treatment (T/°C)

Storage & Handling

- Handling Data

Prefilled liquid products always show a small filler sedimentation.

Before partial use we recommend to stir up carefully the components or to use each container as complete unit.

- Storage Conditions

Store the components in a dry place in tightly sealed original containers. Under these conditions, the shelf life will correspond to the expiry date stated on the label. Partly emptied containers should be tightly closed immediately after use.

Other

- Application Information

Value Units Test Method / Conditions Mix Ratio 1.0 %(W) %(W) Hardener : Resin