Enhanced TDS

Identification & Functionality

- Chemical Family

- RTU Product Type

- Technologies

- Product Families

Features & Benefits

Applications & Uses

- Compatible Substrates & Surfaces

- Markets

- Applications

Technical Details & Test Data

- Cured Properties

Unless otherwise stated, the figures given below have all been obtained from standard test samples made by lapped aluminium alloy parts measuring 114 x 25 x 1.5 mm, the bonding area in all cases being 12.5 x 25 mm. These figures have been determined from typical production batches using standard test methods. They are technical information only and should not be considered as a product specification.

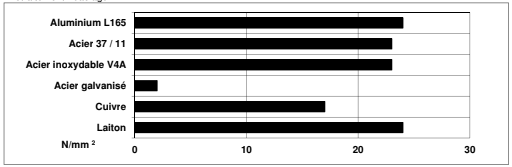

Typical average shear strengths of typical metal-to-metal bonds (ISO 4587)

Cure for 7 days at 23°C and test at 23°C

Pretreatment - sandblasting

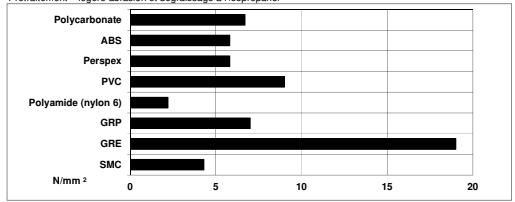

Typical average shear strengths of typical plastic-plastic bonds (ISO 4587)

Cure for 7 days at 23°C and test at 23°C

Pretreatment – light abrasion and degreasing with isopropanol

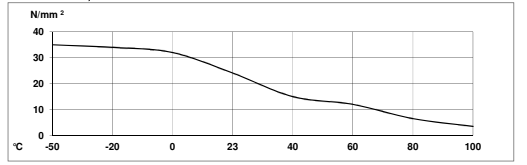

Shear strength as a function of temperature (ISO 4587) (typical average values)

Curing: 7 days at 23°C

Roller Peel Test (ISO 4578) 6 N/mm

Glass Transition Temperature (Tg) No obvious glass transition, refer to the RTC=f(Temperature) and G'=f(Temperature) diagrams.

Tensile Strength (ISO 527) 17 MPa

Elongation at Break: 23%

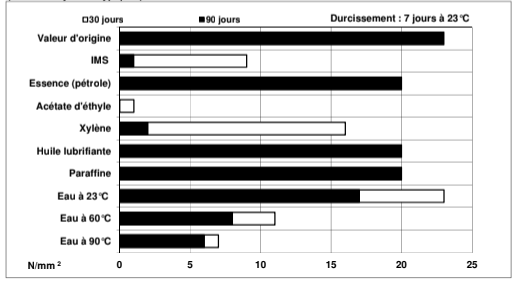

Coefficient of Thermal Expansion (-30oC/+30oC) 80 x 10-6/oK (Cure 7 days at 23oC)Shear strength after immersion in various media at 23°C

(typical average values) Substrate - aluminum

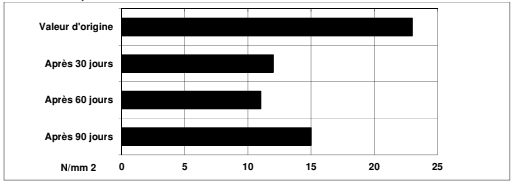

Shear strength in tropical conditions (40/92, DIN 50015: typical average values)

Cure: 7 days at 23°C

Shear modulus G’ (DIN 53345) (typical average values)

Curing: 7 days at 23°C- Processing

Pretreatment

The strength and durability of a bonded joint depend on the quality of the pretreatment of the surfaces to be joined. The surfaces to be bonded must at least be cleaned with a good degreasing agent such as acetone or methoxypropanol or other proprietary degreasers to remove all traces of oil, grease, or dust. Alcohol, gasoline, or paint thinners should never be used. The strongest and most durable joints are obtained by mechanical abrasion or chemical etching (“pickling”) of the degreased surfaces. Abrasion must be followed by a second degreasing.

Adhesive Application

Depending on the application method, the lacquer hardener can be applied by spray, brush, roller, or by dipping the two surfaces to be bonded. The lacquer dries sufficiently after 4 minutes for assembly, transport, or storage. Surfaces coated with the lacquer hardener can be stored for several weeks without loss of reactivity. Once the hardener is dry, the adhesive is applied to one or both surfaces. The parts are then immediately assembled and held together by contact pressure. Polymerization begins as soon as the adhesive comes into contact with the hardener. The joint may be handled with care after the time required to achieve a tensile-shear strength of 1 N/mm², as indicated on page 2. A thickness of 0.15 to 0.25 mm of adhesive will normally provide the joint with optimal shear strength, although joints up to 0.8 mm can be joined. For joint thicknesses up to 0.4 mm, the varnish hardener only needs to be applied to one surface. For thicknesses greater than 0.4 mm, the varnish hardener should be applied to both surfaces to be joined. The substrates should be joined and maintained in contact as soon as possible after applying the adhesive. Even contact pressure on the joint will ensure optimal curing. If the adhesive is applied to one substrate and the lacquer to the other, this method allows the joining operation to be carried out regardless of the pot life.

Mechanical Processing

Specialized companies have developed dosing, mixing, and application equipment well-suited to industrial applications. Huntsman Advanced Materials is happy to advise its customers on the selection of equipment best suited to their specific needs.

Equipment Maintenance

All tools must be cleaned before adhesive residue hardens. Removing hardened residue is a time-consuming and difficult process. If solvents such as acetone are used for cleaning, personnel must take appropriate precautions and avoid contact with skin and eyes.

Typical times required to achieve minimum shear strength

Temperature °C 10 15 23 40 Curing time to Hours - - - - reach RC > 1N/mm² minutes 5 4 3 2 Curing time to Hours - - - - reach RC > 10N/mm² minutes 8 7 5 3 - Properties

- The hardener can be applied on the material and can be stocked as a pendant for 30 days maximum

- Take 3 minutes after assembling the materials, 5 minutes of duly required before handling the assembly

- Ideal for ferrites

- Low viscosity - ideal for high-speed automated productions

- Good thermal stability and good humidity resistance

Safety & Health

- Handling Precautions

Attention

Huntsman Advanced Materials products can generally be handled safely provided certain precautions normally taken when handling chemicals are observed. For example, uncured materials should not come into contact with food products or cooking utensils, and steps should also be taken to prevent skin contact with these uncured materials, as this may have an adverse effect on people with particularly sensitive skin. Impervious plastic or rubber gloves are normally required, as well as the use of eye protection. People should clean their skin thoroughly at the end of each work period. wash with warm water and soap. Adequate ventilation of the workplace is recommended. Precautions for use are described in more detail in our Safety Data Sheets for individual products. These sheets are available upon request and should be consulted for further information.

Storage & Handling

- Storage Conditions

Araldite® F305 and Varnish Hardener can be stored at 2-80°C if the components are kept in sealed containers. At 230°C, the shelf life is up to 6 months. The expiry date, for storage at 2-80°C, is indicated on the packaging.