Enhanced TDS

Identification & Functionality

- Chemical Family

- Fillers Included

- RTU Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Product Features

- Excellent mechanical and electrical properties

- High resistance to crack formation and thermal shock

Applications & Uses

- Composites Processing Methods

- Cure Method

- Product End Uses

- Processing Information

- EX 6240 / EX 6241 HARDENER is ideally suited for processing by conventional techniques.

- The resin and hardener are premixed separately at 50 - 60°C to avoid filler sedimentation before use.

- The resin and hardener then can be mixed at 50 - 60°C under 2 to 8 mbar vacuum for 0.5 to 1.5 hours depending on part size.

- For production with automatic feeding and mixing, each component shall be degasified and homogenized for at least 45 minutes under 3 to 5 mbars vacuum in the respective storage tanks before use to avoid irregular dosing.

- After dosing and mixing with a static mixer, the system is transported directly to a 10 to 15 mbars vacuum chamber, or directly to the heated APG mold.

- The mixture can be stored at 25°C for approximately 2-3 days.

- For continuous manufacturing, the mixers’ conventional tank should be clean weekly.

- If the machine is idle for more than 48 hours or the piping system is cooled to below 18°C, to avoid filler sedimentation and/or undesired increased in viscosity, the mixer’s and feeder’s piping system shall be cleaned before starting up the machine.

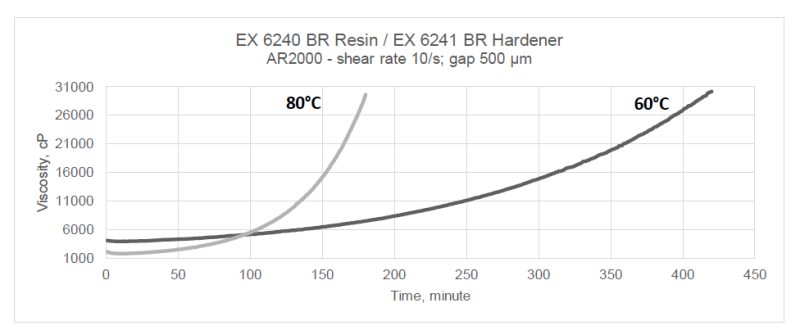

Process Viscosity

The optimum gelation and cure schedule are dependent on the design of the part. When casting large parts with this resin system, an extended cure cycle is recommended to reduce formulation of high stress areas within the cured part.

Molding Temperature

Vacuum conventional casting: 70 – 100 ºC

APG Process: 130 – 160 ºCDemolding Time (Depend on the mold temperature & part volume).

Vacuum conventional casting: 4 – 8 hours

APG Process: 10 - 40 minutesCure Conditions

Vacuum conventional casting: 8 hours at 130°C

APG Process (post minimum cure): 4 hours at 140°C

Typical Physical Properties

Unless otherwise stated, the data were determined with typical production batches using standard test methods. They are typical values only, and do not constitute a product specification.

The values given below were all determined by testing standard samples at 23°C. The test samples were cured 5 hours at 140°C.

Property Value Test Method Tensile Strength, ksi 8.0 - 8.1 ISO 527 Flexural Strength, ksi 14.7 - 14.8 ISO 178 Glass Transition Temperature (DSC), °C 70 - 120 ISO 11357-2 Water absorption (50x50x4mm sample), % weight 10 days at 23°C 0.05 - 0.10 ISO 62 1 hours at 100°C 0.10 - 0.15 ISO 62 Density, g/cc 1.86 - 1.88 ISO EN845/95

Properties

- Physical Form

Safety & Health

- Safety Information

keep out of reach of children

Storage & Handling

- Storage Conditions

- EX 6240 / EX 6241 HARDENER should be stored in a dry place, in the sealed original container, at temperatures between 2°C and 40°C (35.6°F and 104°F).

- Under these storage conditions, the shelf life is 1 year (from date of manufacture). The products should not be exposed to direct sunlight

Other

- Application Information

Value Units Test Method / Conditions Mix Ratio 1.0 %(W) Hardener : Resin - Physical Properties

Value Units Test Method / Conditions Gel Time 420.0-600.0 s at 140°C