Enhanced TDS

Identification & Functionality

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

- Features and Benefits

- Ideal for bonding metals and composites

- Room temperature cure

- High lap shear and compressive strength

- Maximum service temperature up to 400°F (204C)

- Resistant to environmental degradation / aging

- Contains 0.005" spacer beads

- Convenient 2:1 volumetric mix ratio for cartridges or meter mix dispensing

- Low Outgassing per NASA standard

- No Substances of Very High Concern (SVHC) are intentionally added or intentionally present per REACH.

Applications & Uses

- Application Area

- Compatible Substrates & Surfaces

- Markets

- Applications

- Application Information

- EPIBOND® 315 A/B structural adhesive is not only versatile, it can improve production throughput by up to 80%.

- Parts exposed to demanding conditions may require heat resistance and high compressive strength. And on the manufacturing floor, avoiding bottlenecks is key to maximizing productivity.

- With a superior service temperature of 400°F/200°C, EPIBOND® 315 A/B adhesive provides reduced maintenance and increased part lifetime across a wide range of applications. Its high heat resistance and compressive strength enables its use as a liquid shim in areas where metal shims are currently used.

- Curing EPIBOND® 315 A/B adhesive at room temperature is up to 88% quicker than competitive adhesives, with a 75% faster time to handling strength. Easy to use and fast to cure, parts can be made in one working shift.

What makes EPIBOND® 315 A/B structural adhesive different?

EPIBOND® 315 A/B adhesive is a two-component, room-temperature curing epoxy structural adhesive specifically designed for demanding applications requiring high heat resistance and compressive strength.

Property Value Unit Notes T-Peel Strength 2.1 N/mm T-Peel at room temperature Compression (250°F/121°C) 10,000 psi 128% improvement Lap Shear Strength 1,100 psi Designed for 400°F/204°C service

Service Temperature Limit 204 °C Maximum operating temperature

Mix Ratio 2:1 Recommended mix ratio Improved Productivity 80% % Up to 80% improvement in throughput

Regulatory & Compliance

- Quality Standards

Technical Details & Test Data

- Processing Guidelines

- Substrates should be properly surface treated and be free from any contaminants.

- Mix both components thoroughly for several minutes until a homogeneous mixture is obtained.

- Mixing with a centrifugal mixer such as a FlackTek, Hauschild, or Thinky mixer can improve results. Total mixing time at 2000 rpm should be kept below 1 minute to avoid excessive heating.

- Dispensing from a 2:1 dual barrel cartridge through a static mixer is the preferred method.

- The mixed adhesive should be applied to both dry joint surfaces with a spatula.

- A layer of adhesive 0.004 to 0.012 inches (0.1 to 0.3 mm) thick will normally provide the maximum lap shear strength. However, this adhesive has been specifically designed to be effective in layers of up to 0.12 in. (3 mm).

- The components to be bonded should be assembled and clamped as soon as the adhesive has been applied. Even contact pressure throughout the joint area during cure will ensure optimum performance.

- Processing Information

Parameter Value Mix ratios 100:61.5 Per Weight

Mixing color indicator Resin (A): Off-White Hardener (B): Dark Gray Mixed: Gray Viscosity at 1/s shear rate, cP A: 650,000 B: 165,000 Mixed: 300,000 Sag/Slump Test [ASTM D2202] No Sag Static Mixer / Extrusion rate at 80psi 0.50in diameter, 24 element … 75 g/min

Static Mixer / Extrusion rate at 80psi 0.44in x0.44in width, 26 element … 80 g/min

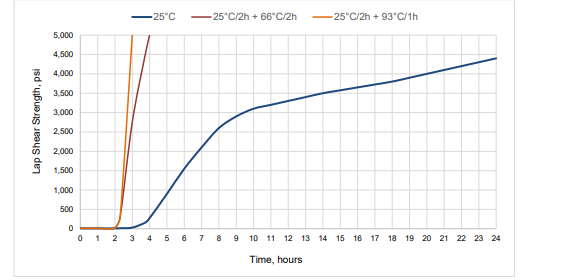

Recommended Cure Schedules 5 days at 77°F (25℃)

77°F/ 2-3 hours + 150°F (66C) / 1-2 hours

77°F/ 2 hours + 200°F (93C) / 45-60 minutes

77°F/ 3 hours + 250°F (121C) / 30-45 minutes

77°F/ 3 hours + 300°F (149C) / 20-30 minutes

Working time (within nozzle) 60 min within nozzle, 30 min for 100g mass

Gel time at 77°F (25℃) 20g / 90 min; 50g / 75 min; 100g / 45 min

- Cured Properties

Unless otherwise stated, the data were determined with typical production batches using standard test methods, and the specimens cured for 5 days at 77°F (25°C). These are typical values and should not be used to establish product specifications.

Property

Value

Unit

Test Method

Condition

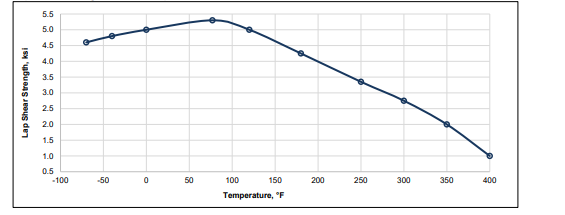

Tensile Lap Shear Strength (Aluminum 2024*, Cured 150°F (66°C) for 1-2 hours) 4,500 psi ASTM D1002 at -55°C Tensile Lap Shear Strength (Aluminum 2024*, Cured 150°F (66°C) for 1-2 hours) 5,500 psi ASTM D1002 at 25°C Tensile Lap Shear Strength (Aluminum 2024*, Cured 150°F (66°C) for 1-2 hours) 4,250 psi ASTM D1002 at 82°C Tensile Lap Shear Strength (Aluminum 2024*, Cured 150°F (66°C) for 1-2 hours) 3,350 psi ASTM D1002 at 121°C Tensile Lap Shear Strength (Aluminum 2024*, Cured 150°F (66°C) for 1-2 hours) 2,750 psi ASTM D1002 at 149°C Tensile Lap Shear Strength (Aluminum 2024*, Cured 150°F (66°C) for 1-2 hours) 2,000 psi ASTM D1002 at 177°C Tensile Lap Shear Strength (Aluminum 2024*, Cured 150°F (66°C) for 1-2 hours) 1,000 psi ASTM D1002 at 204°C Tensile Lap Shear Strength (Aluminum 2024*) 900 psi ASTM D1002 Cured at 25°C/5h

Tensile Lap Shear Strength (Aluminum 2024*) 2,000 psi ASTM D1002 Cured at 25°C/7h

Tensile Lap Shear Strength (Aluminum 2024*) 5,000 psi ASTM D1002 Cured 77°F for 5 days

Tensile Lap Shear Strength (Aluminum 2024*) 4,500 psi ASTM D1002 Carbon Fiber Composite, blasted 200 grit

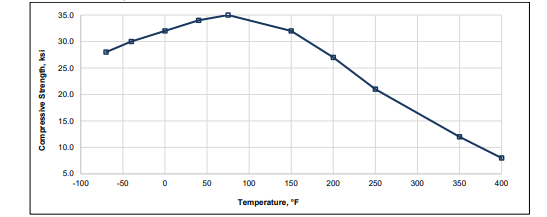

Tensile Lap Shear Strength (Aluminum 2024*) 4,000 psi ASTM D1002 Steel, Blasted Compressive 30,000 psi ASTM D695 at -55°C, Ultimate Strength

Compressive 35,000 psi ASTM D695 at 25°C, Ultimate Strength

Compressive 25,000 psi ASTM D695 at 121°C, Ultimate Strength

Compressive 20,000 psi ASTM D695 at 177°C, Ultimate Strength

Compressive 12,000 psi ASTM D695 at 25°C, 2% Offset Yield

Compressive 14,000 psi ASTM D695 at 177°C, 2% Offset Yield

Compressive 650,000 psi ASTM D695 at 25°C, Modulus

Hardness 85 shore D ASTM D2240 at 25°C Cured Density 1.35 g/cm³ at 25°C Thermal Analysis 125 °C DMA E onset Cured 2 hours at 66°C, Tg

Thermal Analysis TBD °C DMA E onset Cured 1 hour at 93°C, Tg

Thermal Analysis TBD °C DMA E onset Cured 1 hour at 121°C, Tg

Thermal Analysis 127.3 x10⁻⁶ mm/mm/°C Cured 1 hour at 121°C, CTE Above Tg

Thermal Analysis 67.5 x10⁻⁶ mm/mm/°C Cured 1 hour at 93°C, CTE Below Tg

Lap Shear Strength (Aluminum, Anodized and Primed) 5,000 psi ASTM D1002 30 days in water at 25°C

Lap Shear Strength (Aluminum, Anodized and Primed) 5,000 psi ASTM D1002 7 days in Hydraulic Fluid at 49°C

Lap Shear Strength (Aluminum, Anodized and Primed) 5,000 psi ASTM D1002 7 days in Lubrication Oil at 49°C

Lap Shear Strength (Aluminum, Anodized and Primed) 5,200 psi ASTM D1002 7 days in Jet A at 25°C

Tg TBD °C DMA E onset After 7 days at 71°C, 85% RH

Outgassing 0.65% % ASTM E595 TML, Cured 7 days at 25°C

Outgassing 0.02% % ASTM E595 CVCM, Cured 7 days at 25°C

* - Aluminum 2024 T3 Clad, Anodized and Primed

- Lap Shear Strength vs Time Graph

Strength Development at Room Temperature. Anodized & Primed Aluminum

- Technical Information

Lap Shear Strength versus Temperature

Compressive Strength versus Temperature

Packaging & Availability

- Regional Availability

Storage & Handling

- Storage Conditions

- EPIBOND® 315 A Resin and EPIBOND® 315 B Hardener should be stored in a dry place in their original sealed containers.

- When stored at a temperature between 2°C and 25°C (36°F and 77°F) the shelf life is 24 months from date of manufacture.

- When stored at a temperature between 18°C and 40°C (64°F and 104°F), the shelf life of both components is 12 months from date of manufacture.

- Tightly re-seal all containers immediately after use to prevent contamination.

Other

- Application Information

Value Units Test Method / Conditions Mix Ratio 0.615 %(W) %(W) Hardener : Resin