Enhanced TDS

Identification & Functionality

- Chemical Family

- RTU Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Product Features

- Fast curing from 0°C to 40°C (32°F to 104°F)

- Application and curing under water and humid areas

- Excellent bond to a wide range of plastics, composites and metals

- Minimum substrate pretreatment needed

- Suitable for service at temperatures up to 250°F (120°C)

- Excellent ageing and weathering resistance

- Product Features

- Fast curing from 0°C to 40°C

- Suitable for service temperatures up to 120°C

- Application and curing under water

- Application and curing in humid areas

- Excellent ageing and weathering resistance

- Minimum pre-treatment needed

Applications & Uses

- Application Area

- Compatible Substrates & Surfaces

- Markets

- Applications

- Processing Information

Pretreatment

The strength and durability of a bonded joint are dependent on proper pretreatment of the surfaces to be bonded, however the methacrylate adhesives can be used effectively with little surface preparation. Ideally joint surfaces should be cleaned with a good degreasing agent such as acetone, iso-propanol (for plastics) or other proprietary degreasing agents in order to remove all traces of oil, grease and dirt. Low grade alcohol, gasoline (petrol) or paint thinners should never be used. The strongest and most durable joints are obtained by either mechanically abrading or chemically etching (“pickling”) the degreased surfaces.

Application of Adhesive

This system is available in cartridges incorporating mixers and can be applied as ready to use adhesive with the aid of the tool recommended by Huntsman Advanced Materials. The resin/hardener mix may be applied manually or robotically to the pretreated and dry joint surfaces. Huntsman's technical support group can assist the user in the selection of a suitable application method as well as suggest a variety of reputable companies that manufacture and service adhesive dispensing equipment. A layer of adhesive 0.25 mm thick will normally impart the greatest lap shear strength to the joint. The joint components should be assembled and secured in a fixed position as soon as the adhesive has been applied.

Temperature of Application

The recommended temperature application range is 0°C to 40°C. If the adhesive is used at a temperature above 40°C, because of the fact reaction, the viscosity will increase so rapidly that a good wetting of the substrate will be difficult to achieve. Therefore above 40°C, the performance of the bond may be limited. For temperature below 0°C, the Araldite® 2050 may be preferred. Warning: the cure reaction can generate a high amount of heat, it is not recommended to mix large amounts of material at room temperature

Equipment Maintenance

All tools should be cleaned with hot water and soap before adhesives residues have had time to cure. The removal of cured residues is a difficult and time-consuming operation. If solvents such as MEK are used for cleaning, operatives should take the appropriate precautions and, in addition, avoid skin and eye contact.

Typical times to minimum shear strength on sandblasted aluminium / contact pressure

Temperature °C 0°C 10°C 23°C 30°C 40°C Cure time to reach

LSS > 1 MPahours minutes 90 30 15 10 6 Cure time to reach

LSS > 10 MPahours 2 minutes 50 25 15 10

Properties

- Physical Form

Technical Details & Test Data

- Processing Condition

- Pretreatment: The strength and durability of a bonded joint are dependent on proper treatment of the surfaces to be bonded. At the very least, joint surfaces should be cleaned with a good degreasing agent such as acetone, iso-propanol (for plastics) or other proprietary degreasing agents in order to remove all traces of oil, grease and dirt. Low-grade alcohol, gasoline, or paint thinners should never be used. The strongest and most durable joints are obtained by either mechanically abrading or chemically etching (“pickling”) the degreased surfaces. Abrading should be followed by a second degreasing treatment. ARALDITE® 2051 A/B structural adhesive is available in cartridges incorporating mixers

- Application of adhesive: This system is available in cartridges incorporating mixers and can be applied as ready to use adhesive with the aid of the tool recommended by Huntsman Advanced Materials. The resin/hardener mix may be applied manually or robotically to the pretreated and dry joint surfaces. Huntsman's technical support group can assist the user in the selection of a suitable application method as well as suggest a variety of reputable companies that manufacture and service adhesive dispensing equipment. A layer of adhesive 0.25 mm thick will normally impart the greatest lap shear strength to the joint. The joint components should be assembled and secured in a fixed position as soon as the adhesive has been applied.

- Temperature of application: the recommended temperature application range is 0°C to 40°C (32 to 104°F). If the adhesive is used at a temperature above 40°C, because of the fact reaction, the viscosity will increase so rapidly that a good wetting of the substrate will be difficult to achieve. Therefore above 40°C (104°F), the performance of the bond may be limited. For temperature below 0°C (32°F), the ARALDITE® 2050 may be preferred.

Cure times to reach minimum shear strength (sandblasted aluminum)

Temperature 0°C (32°F) 10°C (50°F) 23°C (73°F) 30°C (86°F) 40°C (104°F) >1MPa (145 psi) 90 min 30 min 15 min 10 min 6 min >10MPa (1,450 psi) 2 h 50 min 25 min 15 min 10 min - Equipment Maintenance All tools should be cleaned with hot water and soap before adhesives residues have had time to cure. The removal of cured residues is a difficult and time-consuming operation. If solvents such as acetone are used for cleaning, operatives should take the appropriate precautions and, in addition, avoid skin and eye contact.

- Typical Cured Properties

Unless otherwise stated, the figures given below were all determined by testing standard specimens made by lapjointing 114 x 25 x 1.6 mm strips. The joint area was 12.5 x 25 mm in each case. The figures were determined with typical production batches using standard testing methods.

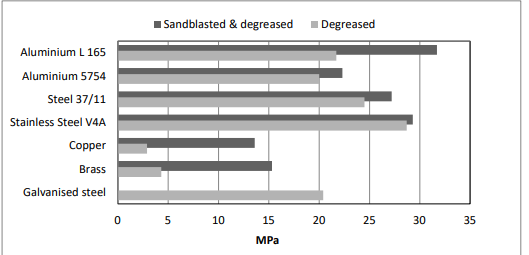

Average lap shear strengths of typical metal-to-metal joints (ISO 4587) (typical average values) Cured for 24 hours at RT and tested at 23°C, sandblasted and degreased with acetone or only degreased with aceton

Notes: Araldite® 2051 is not suitable to bond copper or brass without surface preparation. Galvanised steel should not be abraded or sandblasted, better results are obtained with only degreasing.

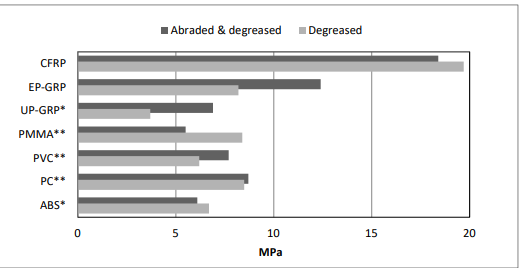

Average lap shear strengths of typical plastic-to-plastic joints (ISO 4587) (typical average values) Cured for 24 hours at RT and tested at 23°C. Abraded and degreased with isopropanol or only degreased with isopropanol.

(*): UP-GRP, ABS, substrate failure observed when abraded and degreased. (**) : PMMA, PVC, PC, substrate failure observed in all conditions.

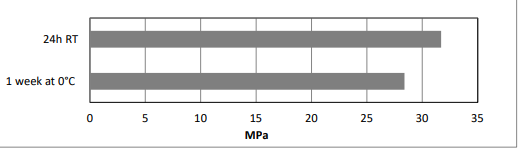

Average lap shear strengths on aluminium after bonding and cure at low temperature (ISO 4587) (typical average values) Bonded and cured at the temperatures indicated below. Test on aluminium sandblasted and degreased. Tested at 23°C just after release of the specimens from the climatic chamber.

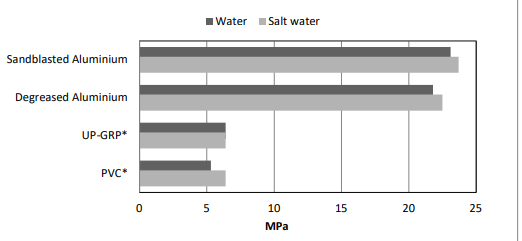

Average lap shear strengths after application, bonding and curing under water (ISO 4587) (typical average values) Cure 24 hours under water at RT.

(*): UP-GRP, PVC, substrate failures observed.

Glass Transition Temperature (DMA) (Typical average values) Cure 24 hours at RT

Onset 98°C Midpoint 127°C Tensile Properties (ISO 527) (Typical average values) Cure 24 hours at RT and test at 23°C break ca. 10%

Tensile Strength 40 MPa Tensile Modulus 1700 MPa Elongation at break ca. 10%

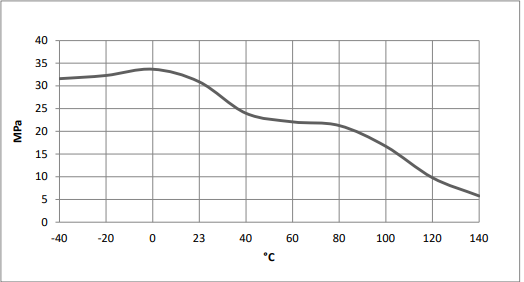

Lap shear strength versus temperature (ISO 4587) (typical average values) On aluminium, pretreatment: sand blasting. Cure: 24 hours at RT.

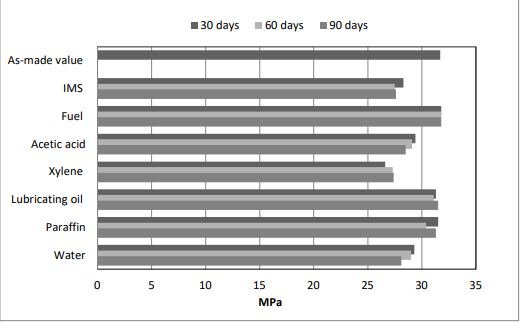

Lap shear strength versus immersion in various media (ISO4587) (typical average values) On aluminium, pretreatment: sand blasting. Cure: 24 hours at RT Tested at 23°C. LSS. was determined after immersion for 30 days at 23°C

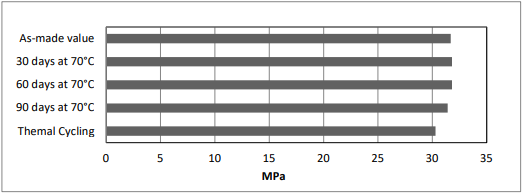

Lap shear strength versus heat ageing and thermal cycling (typical average values) Cure: 24 hour at RT. Test at 23C Thermal cycling 100 cycles ( 2h -30°C / 1 h up to 70°C / 2h 70°C / 1h down to -30°C)

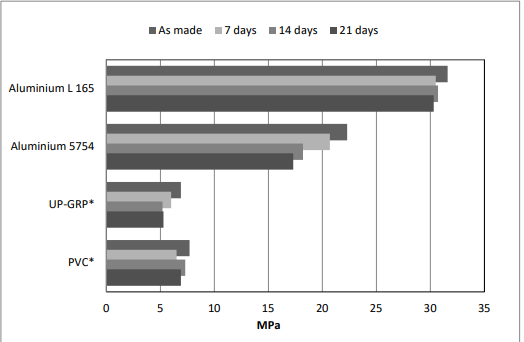

Lap shear strength versus Cataplasma ageing (typical average values) Cure 24 hours at RT – Cataplasma according to ISO 9142/E2 - Test: at 23C Metals sandblasted and degreased / plastics abraded and degreased

Packaging & Availability

- Regional Availability

Storage & Handling

- Storage Conditions

- Araldite® 2051 may be stored during 24 months at 2 – 8°C provided the components are stored in the original sealed containers.

- The expiry date is indicated on the packaging.

- The product may be placed at room temperature before use, the total time at room temperature should not exceed 9 months

- Long term exposure above 25°C will reduce the shelf life of the product.

- Storage Conditions

- ARALDITE® 2051 A/B Adhesive should be stored in a dry place, in the original sealed containers, at temperatures between 2°C to 8°C (36°F to 46°F).

- Under these storage conditions, the product has a shelf life of 24 months from date of manufacture.

- The expiry date is indicated on the package. The product should not be exposed to direct sunlight.

- The product may be placed at room temperature before use, the total time at room temperature should not exceed 9 months.

- Long term exposure above 25°C (77°F) will reduce the shelf life of the product. The product should be never frozen.

- Handling Precautions

- Our products are generally quite harmless to handle provided that certain precautions normally taken when handling chemicals are observed.

- The uncured materials must not, for instance, be allowed to come into contact with foodstuffs or food utensils, and measures should be taken to prevent the uncured materials from coming in contact with the skin, since people with particularly sensitive skin may be affected.

- The wearing of impervious rubber or plastic gloves will normally be necessary; likewise the use of eye protection.

- The skin should be thoroughly cleansed at the end of each working period by washing with soap and warm water.

- The use of solvents is to be avoided. Disposable paper - not cloth towels - should be used to dry the skin. Adequate ventilation of the working area is recommended

Other

- Application Information

Value Units Test Method / Conditions Mix Ratio 1.0 %(W) %(W) Hardener : Resin - Physical Properties

Value Units Test Method / Conditions Density 1.0 g/cm³ g/cm³