Enhanced TDS

Identification & Functionality

- Chemical Family

- RTU Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Key Features

- “No-mix” adhesive – components can be applied to separate surfaces or beads

- 2 minute pot life, 5 minute initial cure strength

- Ideal for ferrite bonding

- Low viscosity – ideal for fast production line bonding.

- Excellent thermal stability and resistance to heat and humidity

- Product Features

- AGOMET® F 305 A/B is reaction adhesives for bonding of metals and plastics. Thanks to their very high curing rates, the adhesives are ideally suited for bonding operations where, e.g. in series production, a short potlife is required. Especially for the production of loudspeakers in different sizes, AGOMET® F 305 A/B is proven very successful.

- The adhesives have a potlife of 1 - 2 minutes. As soon as 2 - 4 min. after bonding and curing at room temperature, the parts can be handled. The final strength is reached after appr. 2 hours.

- Bonds produced with AGOMET® F 305 A/B is shock- and peel resistant and have a good moisture resistance. Both AGOMET® F 305 A/B come as a two part system and can be applied 1:1 with standard dosing/dispensing equipment. In many cases, a particular surface preparation of the parts to be bonded is not necessary or can be reduced to a minimum.

- Bondable materials : Metals such as steel, aluminium, copper and their alloys, ferrites. Plastics such as ABS, polystyrene, rigid PVC, polycarbonate, polyphenylene oxide, moulded polyester parts, hard paper, and others. Materials on a cellulose and wood basis such as loudspeaker membranes and chip boards.

- Product Features

Bondable materials : Metals such as steel, aluminium, copper and their alloys, ferrites. Plastics such as ABS, polystyrene, rigid PVC, polycarbonate, polyphenylene oxide, moulded polyester parts, hard paper, and others. Materials on a cellulose and wood basis such as loudspeaker membranes and chip boards.

Applications & Uses

- Application Area

- Compatible Polymers & Resins

- Compatible Substrates & Surfaces

- Markets

- Applications

Properties

- Physical Form

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Pre Processing Data

Preprocessing

The strength and durability of the bond depends on proper preparation of the bonding surfaces. However, acrylic adhesives can achieve satisfactory results without pre-treatment of the surface. In any case, the bonding surfaces should be cleaned with a degreasing cleaner such as acetone, isopropyl alcohol (for plastics), or other suitable cleaning agents to remove all oil. stains, dirt and dust. Do not use low-purity alcohol, gasoline or paint thinners. The cleaned surface can be obtained by mechanical grinding or chemical etching. The strongest, most durable bond.

Adhesive Application

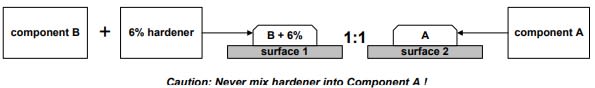

The two-component adhesive is applied directly to the prepared, dry bonding surface. Although the bonding gap can be up to 0.8 mm, a layer of 0.15 to 0.25 mm thick usually gives the greatest lap shear strength to the bond. The bonded parts should be clamped immediately after application of the adhesive. Using uniform contact pressure ensures optimal curing of the bond area. Add 4 to 10 % (6 % is optimal) of curing powder or curing glue to component B and mix evenly, then add to the prepared component A in a 1:1 ratio. Mix. Apply Part A to one surface to be bonded, then apply an equal coat of Part B (containing the curing agent) to the other surface. The two parts are bonded and clamped with uniform contact pressure. Since the adhesive only begins to cure when the two surfaces come into contact, this single process allows forNote: Do not mix hardener into component A

As an alternative to the single processing method (A/B process), the two components A and B (without hardener) can be mixed in a 1:1 ratio beforehand. AGOMET® F 305 is a "normal" reactive adhesive that can only be used after adding 2 - 5 % of curing powder or glue immediately before the actual bonding process

- Processing Information

Even without a particular surface preparation, AGOMET® F 305 A/B develop high strength values, e.g. when bonding loudspeaker parts. As with all bonds, however, the bonding strength can be optimised by additional surface pretreatment: the parts must be free of loose impurities such as dust, oxides, grease, mould release agents, or plasticizers. A simple surface wipe with a solvent such as ethyl acetate (for plastics: alcohol) is adequate. Normal residues of rolling or drawing oil are relatively compatible with AGOMET® F 305 A/B and can remain on the surfaces to be joined.

Application Weight: The most favourable amount of adhesive to be applied is 150 - 250 g/m³

Mixing Ratio: Add 4 to 10 % - preferably 6 % - hardener powder to component B and mix homogeneously. Then apply 1:1 together with the ready-to-use component A.

Bonding: Apply component A to one surface and place an equally thick layer of component B (hardener already mixed in) on the other surface. Then the two surfaces are mated and kept under contact pressure. Curing starts only after both surfaces to be bonded have been joined. This separate processing allows bonding operations practically independent of the adhesive's potlife.

Bonding continued: You may also apply the adhesive with dosing/dispensing equipment, even by placing components A and B (incl. hardener) on top of each other on one of the surfaces to be joined. In this case, however, the parts must be mated immediately.

Bonding Performance

Tensile Shear Strength

Aluminium/Bondur F 44 (AlCuMg₂): appr. 25

Brass: appr. 25

Steel: appr. 23

Rigid PVC: appr. 10 (mb)Peel Strength Aluminium/AlF 13.3 N/mm: appr. 2 (measured in the T-Peel Test according to DIN 53 282, test specimen: 130 x 30 x 0.5 mm; pretreatment: roughened)

Resistance to Chemicals: AGOMET® F 305 A/B have good resistance against diluted mineral acids and alkalis, gasoline and diesel fuels. Joints produced with AGOMET® F 305 A/B also show good stability under the effects of moisture and heat (tropical climate), as well as under the influence of aqueous solutions.

Safety & Health

- Handling Precautions

Our products are generally quite harmless to handle provided that certain precautions normally taken when handling chemicals are observed. The uncured materials must not, for instance, be allowed to come into contact with foodstuffs or food utensils, and measures should be taken to prevent the uncured materials from coming in contact with the skin, since people with particularly sensitive skin may be affected. The wearing of impervious rubber or plastic gloves will normally be necessary; likewise the use of eye protection. The skin should be thoroughly cleansed at the end of each working period by washing with soap and warm water. The use of solvents is to be avoided. Disposable paper - not cloth towels - should be used to dry the skin. Adequate ventilation of the working area is recommended.

Packaging & Availability

- Regional Availability

Storage & Handling

- Storage Conditions

- Shelf life: Please see labels: a minimum of 6 months in the original unopened container.

- Storage Condition: Once the hardener has been mixed in, component B can only be stored for about one week.

- Storage Information

AGOMET® F305 A have a shelf life of 36 months when stored at 2 - 8 °C in unopened containers. At 23°C, they have a shelf life of 6 months. The shelf life at 2 - 8°C can be found on the container label. Once component B has been mixed with the curing powder, the shelf life of this component is reduced to 2 - 3 weeks.

Other

- Appearance

- White Powder

- Application Information

Value Units Test Method / Conditions Mix Ratio 1.0 %(W) %(W) Hardener : Resin - Physical Properties

Value Units Test Method / Conditions Lap Shear Strength min. 25.0 MPa MPa at 23°C